Swiss type CNC lathes are sophisticated machines that provide exceptional precision and efficiency in manufacturing small, intricate components. Proper care and maintenance are essential to maximize their lifespan and ensure consistent performance. By following best practices, manufacturers can reduce downtime, prevent costly repairs, and maintain high-quality production over the long term.

Regular Maintenance and Inspection

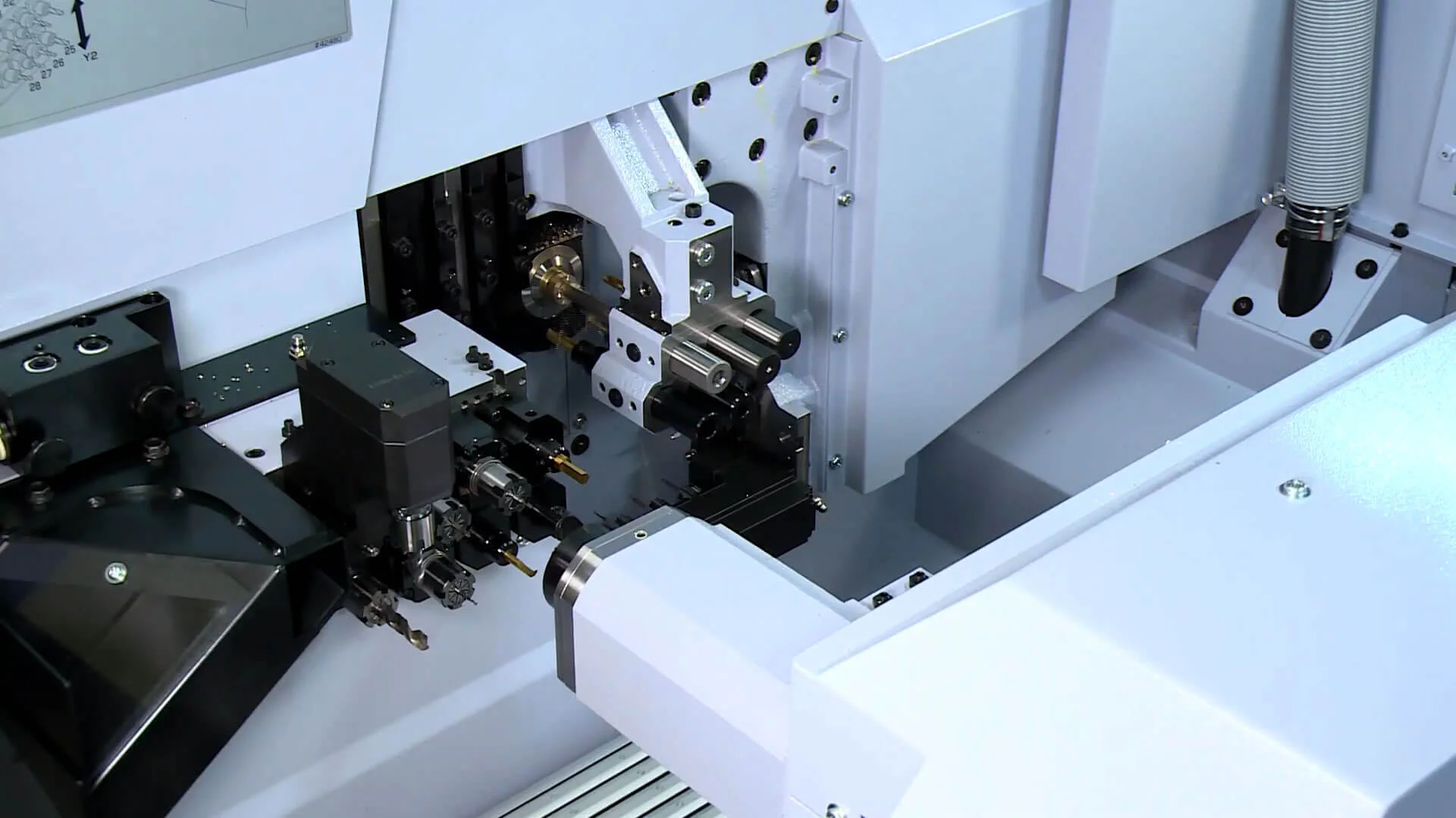

Routine maintenance is the foundation of extending the lifespan of a Swiss type CNC lathe. Regularly inspecting key components such as spindles, guide bushings, linear motion systems, and tool holders helps identify wear or damage before it leads to major issues. Lubrication schedules should be followed meticulously, as inadequate lubrication can increase friction, cause overheating, and accelerate component wear. Periodic cleaning of the machine, including coolant systems and work areas, prevents debris accumulation that can impair precision and lead to mechanical failures.

Proper Operation and Training

Correct operation is equally important for longevity. Operators should be thoroughly trained in using a Swiss type CNC lathe, understanding both its capabilities and limitations. Avoiding overloading the machine, using the correct cutting tools, and following recommended feed rates and spindle speeds prevent excessive stress on the components. Consistent adherence to operational guidelines reduces the risk of errors, vibrations, and mechanical strain that could shorten the machine’s service life.

Investing in a high-quality swiss type cnc lathe ensures that the machine is built with durable components and precision engineering, which inherently supports a longer lifespan. Even with a robust machine, proper usage and adherence to manufacturer-recommended practices are essential to fully realize its durability benefits.

Monitoring and Adjusting Machine Settings

Modern Swiss lathes often feature advanced CNC controls that allow precise adjustments to optimize performance. Monitoring these settings and calibrating the machine regularly ensures that tolerances remain consistent and tools are not subjected to unnecessary stress. Misaligned or incorrectly calibrated systems can increase wear on spindles and guide bushings, leading to reduced accuracy and potential component failure. Proactive calibration and adjustment prevent minor issues from developing into significant problems.

Coolant Management

Proper management of coolant systems is another critical factor in extending the lifespan of a Swiss type CNC lathe. Using the appropriate coolant for the material being machined, maintaining correct flow rates, and ensuring the system is free from contamination all contribute to reducing heat and friction during operations. Efficient cooling minimizes thermal stress on machine components, preserves cutting tool life, and maintains consistent machining precision.

Tool Maintenance and Replacement

The condition of cutting tools directly impacts the machine’s performance and longevity. Dull or damaged tools increase cutting forces, causing strain on spindles and other mechanical parts. Regularly inspecting and replacing worn tools, using the correct type for the material, and ensuring proper tool alignment are essential practices. Maintaining tool quality not only improves part accuracy but also reduces wear on the machine itself.

Environmental Considerations

The environment in which the lathe operates can also affect its lifespan. Maintaining a clean, temperature-controlled workspace with minimal vibration protects the machine from external stressors. Excessive dust, humidity, or temperature fluctuations can negatively impact mechanical components and electronic systems, leading to premature wear or failure. Ensuring a stable operating environment supports long-term reliability and consistent performance.

Conclusion

Extending the lifespan of a Swiss type CNC lathe requires a combination of regular maintenance, proper operation, careful monitoring, and attention to environmental factors. By following best practices such as routine inspections, correct coolant use, precise calibration, and tool management, manufacturers can maintain the machine’s precision, reduce downtime, and avoid costly repairs. Investing in operator training and adhering to manufacturer guidelines ensures that a Swiss type CNC lathe delivers consistent performance and long-term value for years of high-quality production.