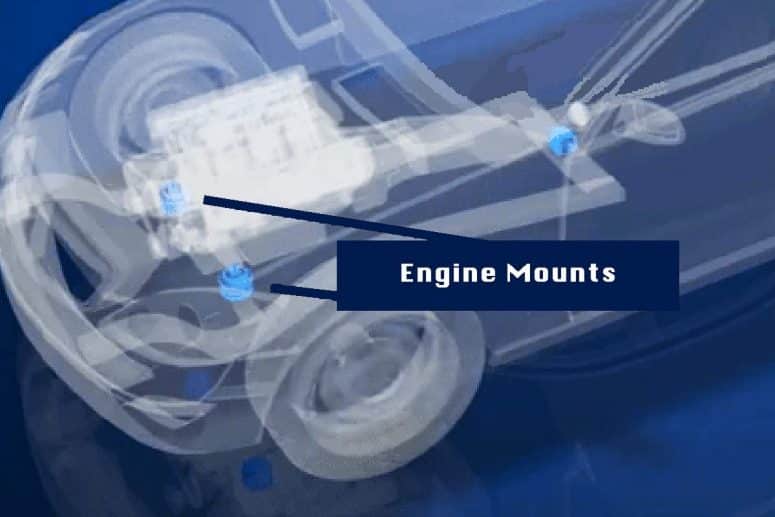

Engine mounts are a critical yet often overlooked component in any vehicle or piece of machinery. They serve a dual purpose—securing the engine in place and isolating the vehicle chassis from engine vibrations. Selecting the correct engine mount is vital for maintaining performance, comfort, and safety, whether in cars, trucks, agricultural equipment, or marine engines.

While many drivers and operators rarely think about them, engine mounts play a major role in how smooth a vehicle feels on the road and how long other engine-connected systems last. For those looking to replace or upgrade these parts, engine mounts are available in a wide range of types and configurations to meet the needs of various vehicles and applications.

What Are Engine Mounts?

At their core, engine mounts are brackets designed to fix the engine to the frame or subframe of the vehicle. Most mounts are composed of a combination of metal and rubber, while others incorporate fluid or electronic components for more refined performance.

A high-quality engine mount prevents the engine from excessive movement while absorbing vibrations and shocks that occur during acceleration, braking, and rough terrain driving. Different designs exist to meet specific engineering goals, whether it’s minimizing noise, optimizing performance, or handling more torque.

Common Types of Engine Mounts

Understanding the different types of engine mounts helps in selecting the right fit based on engine type, vehicle class, and usage patterns. Below are the most widely used variants:

1. Rubber Engine Mounts

Rubber mounts are the most common type found in standard vehicles. They consist of a metal frame bonded to rubber pads, which provide cushioning between the engine and the frame. The rubber dampens vibrations and limits noise transmission into the cabin.

Use case:

Ideal for standard passenger vehicles where comfort and cost-efficiency are primary concerns. They provide reliable performance for everyday driving.

Pros:

- Cost-effective

- Reduces vibrations and noise

- Long-lasting under normal driving conditions

Cons:

- Rubber can degrade over time

- Not suitable for high-performance or high-torque applications

2. Hydraulic Engine Mounts

Hydraulic mounts use a combination of rubber and hydraulic fluid. The fluid helps to absorb more intense vibrations and offers better performance under varying load conditions. These mounts can adapt to different engine operating modes by changing fluid pressure.

Use case:

Common in luxury or high-end vehicles for enhanced comfort and smooth engine performance.

Pros:

- Superior vibration control

- Excellent for smooth and quiet rides

- Responsive to engine load changes

Cons:

- More expensive than rubber mounts

- Can leak fluid over time

3. Solid/Polyurethane Mounts

Solid or polyurethane mounts are typically used in high-performance or racing applications. Instead of absorbing vibration, they focus on keeping the engine firmly in place, which helps in maintaining consistent engine alignment and power delivery.

Use case:

Performance vehicles, race cars, and off-road vehicles where precision and power are prioritized over comfort.

Pros:

- High durability

- Minimal engine movement

- Improved throttle and handling response

Cons:

- Transmits more vibration into the vehicle

- Can lead to a harsher ride

4. Electronic or Active Engine Mounts

These advanced mounts incorporate sensors and actuators to actively dampen vibrations in real time. By adjusting the stiffness of the mount based on engine activity and road conditions, they offer the best balance of comfort and performance.

Use case:

Found in premium vehicles and some newer hybrid or electric cars.

Pros:

- Optimized vibration control

- Intelligent adaptation to driving conditions

- Enhances overall driving experience

Cons:

- Complex and expensive

- Costly repairs if electronics fail

5. Marine and Industrial Mounts

Engine mounts used in boats and industrial machinery are specially designed to handle different environmental challenges like saltwater exposure or prolonged vibration. These mounts often feature corrosion-resistant materials and heavy-duty construction.

Use case:

Marine engines, generators, agricultural and construction equipment.

Pros:

- Built to handle tough conditions

- Protects against long-term vibration damage

- Engineered for stability and reliability

Cons:

- Specialized and may not be interchangeable with automotive mounts

- Can be more expensive due to build quality

Selecting the Right Engine Mount

When choosing an engine mount, consider the following:

- Engine size and power output: Heavier or high-torque engines need stronger mounts.

- Vehicle type and usage: Daily drivers require comfort-focused mounts, while race or utility vehicles benefit from rigid mounts.

- Budget and maintenance goals: Balance performance needs with cost and ease of maintenance.

Consulting with a technician or parts specialist can also help ensure compatibility with your specific vehicle model.

Conclusion

Engine mounts are more than just supports—they’re essential to ensuring your engine performs efficiently and your ride remains smooth and safe. With several types available—from basic rubber mounts to advanced electronic systems—understanding their differences and uses helps you make the right choice based on your needs.

Whether you’re performing a routine replacement or upgrading for better performance, investing in quality engine mounts suited to your application will pay off in vehicle stability, longevity, and comfort.